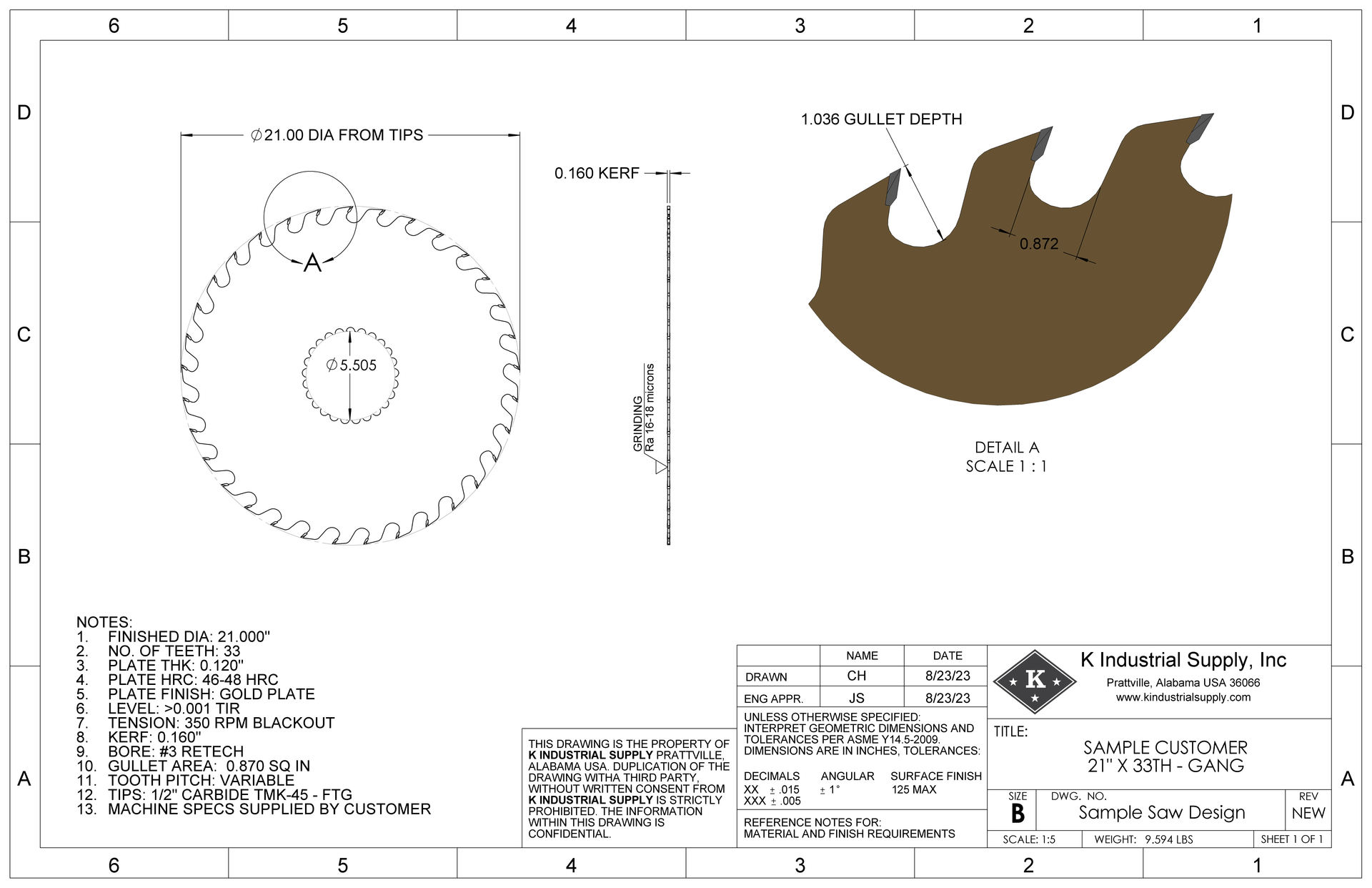

Optimized Saw Design

With over 30 years in the industry, our team of experts can help optimize your saw design resulting in the ability to decrease target size while allowing increased feed speeds. We work with the sawmill to discuss problems with current state and propose solutions to achieve the future state of increased runtime or increased feed speeds.

We use a software program that has been developed through many years of data and research in which we can input specific parameters from your sawmill to determine an optimal saw to run in your mill. We take into consideration the percentage of 2" x 4" vs 2" x 12" boards manufactured, the size of the cants in correlation to the feed speeds along with the guide clearance setting to help calculate the number of teeth, gullet capacity, and profile shape best suited for your sawmill.

We have developed saws for RPM, USNR, Optimil, Comact, Cone and many other gang and quad box machine centers. Our customers greatly benefit from our engineering services. Let us help you become more productive today!

(334) 290-1801

163 Medical Center Drive

Prattville, AL 36066

Powered by UNO CMS | Designed by Productive I.T.